After the overwhelming success of van Gijs Grote Tuinverbouwing©, where we introduced you to the wonderful world of gardening. Presenter Gijs van der Meijde will take you on a new DIY adventure. In Gijs Grote Garageverbouwing© he exchanges nature for a real man cave.

The houde, acquired in April 2019, featured an old garage. A previous occupant was a car enthusiast and regularly tinkered with the vehicles he loved so much. Unfortunately, Gijs does not share these ambitions, and because of this the garage has quickly become a storage for old furniture and other materials.

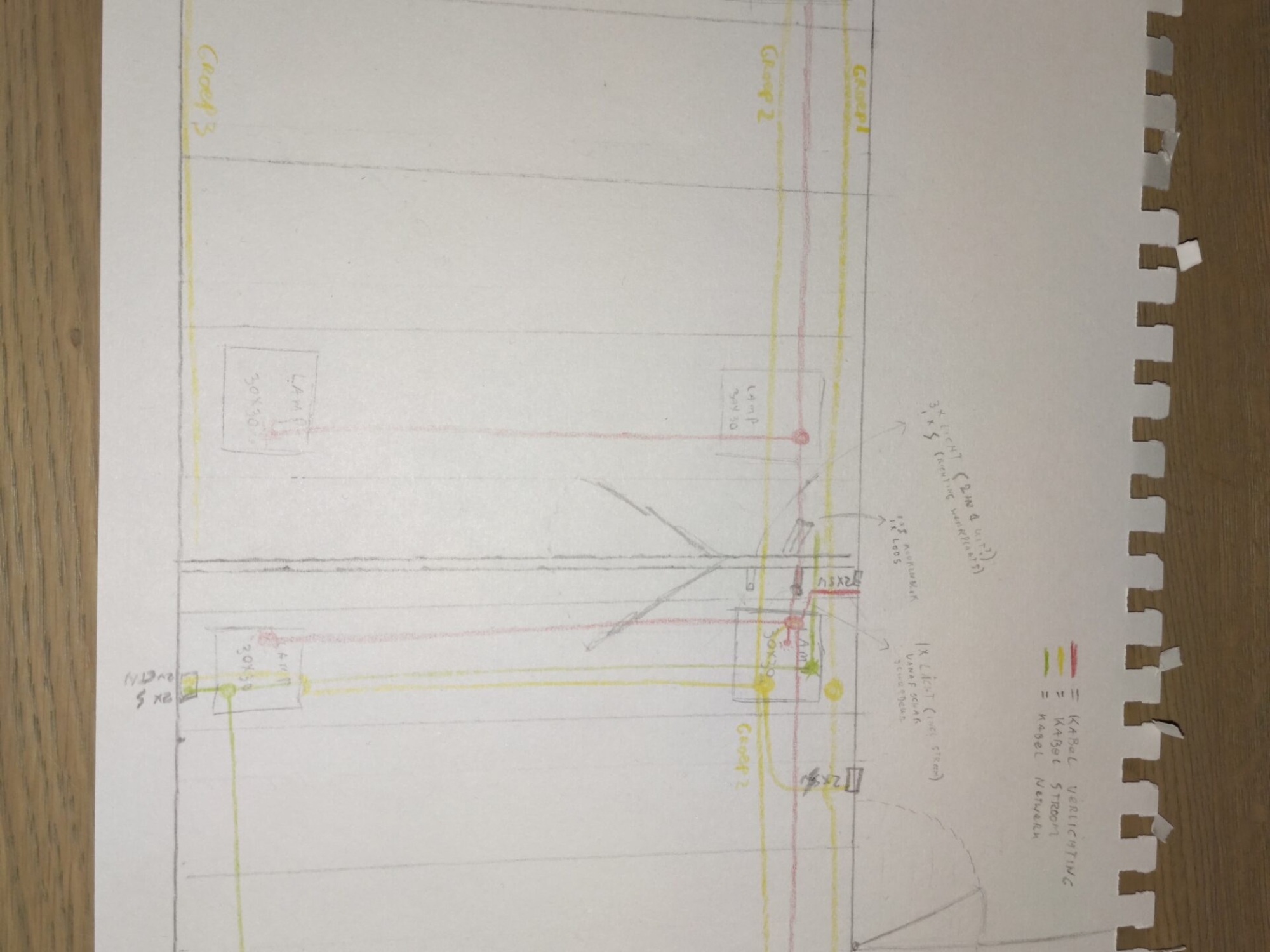

Because Gijs is a tinkerer by nature, and spends a lot of time at the computer for his work, he decided to transform the garage into a true man cave with a workshop and an office. The image below is an early sketch of what the garage could eventually become.

Before Gijs could start on this heavy job, however, the garage had to be cleaned up and the walls cleared. So there’s work to be done!

In order to give the office a sleek look, the walls are covered with plaster. For this, however, a frame had to be placed first, with which the electricity was already taken into account. The power boxes in these photos are replaced, for a professional finish it was decided to use special “hollow wall” boxes. Because a plaster wall is not very sturdy, and it was not yet clear whether things should eventually hang on the walls, it was decided to cover the frame with wooden plates first. This gives the walls a bit more body and makes it easier to place shelves and / or paintings in the future.

Next, it was time to do the floor, to easily create a level surface Gijse decided to level the concrete subfloor. After this, a frame could be placed in which pipes could be concealed, such as the water and sewer and electricity for a kitchen unit. Ultimately, the floor was paneled with underlayment plates. A final floor (laminate, PVC, carpet) can be applied later on. In the meantime, the new “hollow wall” boxes for the sockets and light switches have also been installed.

After installing the subfloor and walls, the finishing could begin. To prevent paint from ending up on the final floor, Gijs started plastering and painting the walls. A matte white paint has been chosen for a simple yet professional look.

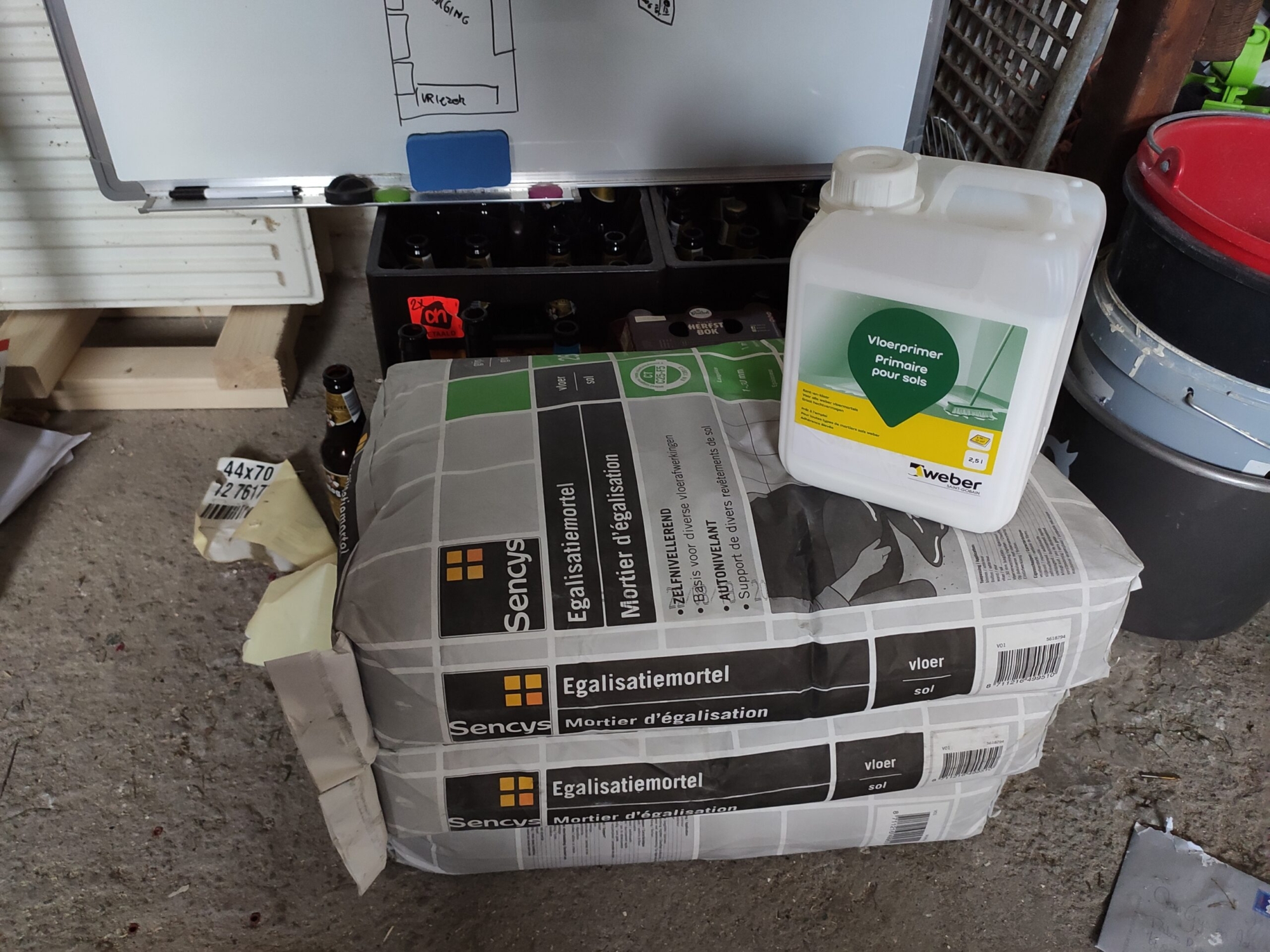

Up to 10% of the heat can be lost through an uninsulated floor. So before the floor is finished, it is insulated with HR ++ EPS Pearls. This is an inexpensive way to save a lot of energy. Because the floor in the office has to endure the rolling of office chairs and for example sand coming in, a sturdy PVC floor was chosen. These floors are easy to clean and are more durable than laminate and most woods.

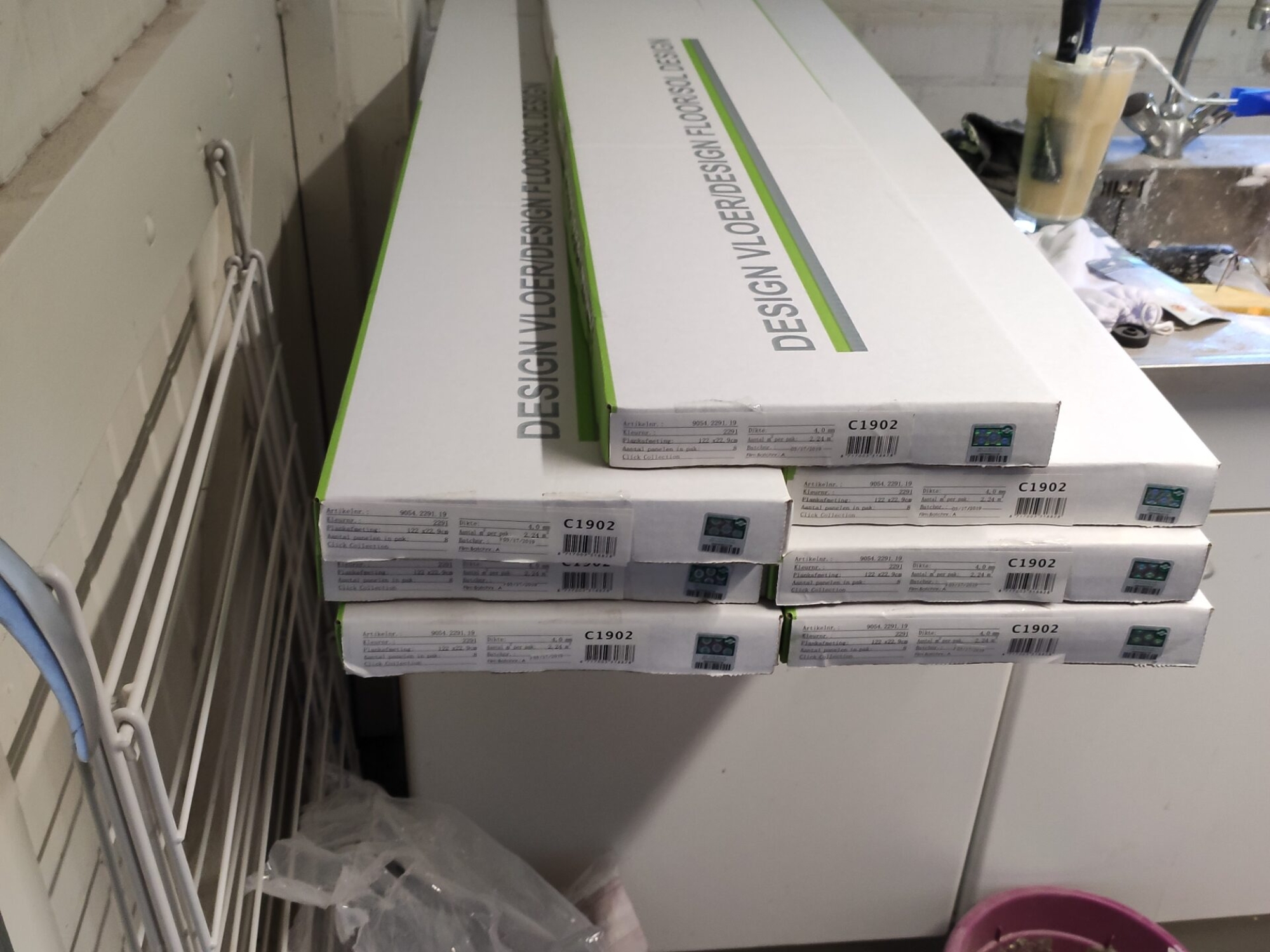

Meanwhile, winter was beginning to set in. To make the jobs a bit more comfortable, the original radiator has been placed back. The office also has a small kitchen area with running water, so fresh coffee is always within reach. For this project it was decided to install a custom-made kitchen. A simple kitchen block measuring 100x60cm was used as a basis. A solid birch countertop with a modern stainless steel sink and tap is mounted on this. For a cleaner look, it was decided to paint the doors with a metallic red paint, and to install stainless steel handles. Due to the great distance to the boiler of the house, it was decided not to run a hot water pipe to the garage, instead a small boiler was installed. This makes hot water available quickly.

To save even more energy and to better regulate the temperature in the garage, the ceiling is insulated with rockwool. Unfortunately, the original electricity in the garage was not sufficient to safely provide the office and workshop. That is why it was decided to replace it with a new system in which electricity, internet and light run through separate networks. On our Gijs Grote Tuinverbouwing© blog you can see how new pipes were installed between the garage and the house, including a new electricity cable from the fuse box in the house.

The garage is very spacious with its 23.5 m2. To prevent this from feeling like two small spaces because of the split between office and workshop, it was decided to have a glass partition installed. In connection with the insurance, or the lack thereof, this wall was placed by a professional. The result is impressive!

After the ceiling has been insulated and the electricity installed, it could also be finished. Because the office is a bit on the low side, every centimeter counts. This is the reason for abandoning the original plan for a suspended ceiling, which is very practical for future modifications, and opting for a plaster ceiling. To do this, battens were first mounted between the beams, on which the plasterboards were stapled. Then the ceiling, like the walls, were plastered and painted. With the ceiling off, the office really starts to take shape.

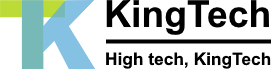

Until now, the workshop part of the garage has remained largely untouched. Time to change this. The floor of the workshop was badly damaged, so it was decided to fill it with special leveling mortar. Because no new floor is installed on top of the concrete floor in the workshop, a special mortar with reinforced fibers was used. Strong concrete paint must prevent the floor from being damaged, and also provide a waterproof finish that makes the workship easy to keep clean. The cover of the grease pit forms a kind of pier in the middle of the workshop.

Because the old inspection pit can no longer perform its function, it is reused as storage. The inspection pit is more than a meter wide, so there is enough space for a row of racks. This means that materials and tools that are used less often are always nearby.

After the floor and the walls in the workshop have been painted, it is finally time to decorate. First, a shelf is placed for the 3D printers. This one is made from leftover countertop in the office. Next to this comes the KingTech server. Due to its height, it cannot be placed completely in the corner as this would block the light switch.

Nothing in Gijs Grote Garageeverbouwing © is pre-fabricated, and neither are the desks. To maintain the style of the countertop and the previously made shelf, it was decided to make 2 spacious desks from beech wood. Two spacious table tops were used for this, which, after being lacquered, have the same color and finger-joint style. To carry the desk-tops, two electrically adjustable bases have been chosen. This allows the desks to be changed in height at the touch of a button. The desks have a bluetooth connection, which means that personal heights can be saved and adjusted using an app. The worktops are mounted with M8 bolts, for which a screw thread is applied in the desk-top. This way of mounting makes it possible to disassemble and reassemble the worktop without damaging it, normal screws damage the wood so that a worktop can never be mounted as firmly as the first time. Because the worktop can move up and down, cables can become trapped between the wall and the worktop. To prevent this, a robust metal cable gland is placed in each worktop.

Once the desks are in place, the rest of the furniture can also be moved. Every desk gets a PC, so there are two equal workstations. A bookcase and 2 display cabinets fill the back wall and temporary office chairs make the office ready for use. This means that, although there are still some minor things to be done, the office will be put into use from now on. All updates for Gijs Grote Garageeverbouwing © are from this moment also written from the new office.

Because there will be a lot of work to be done in the new office, a good office chair is essential. An ergonomic chair made of high-quality materials has been selected from this point of view.

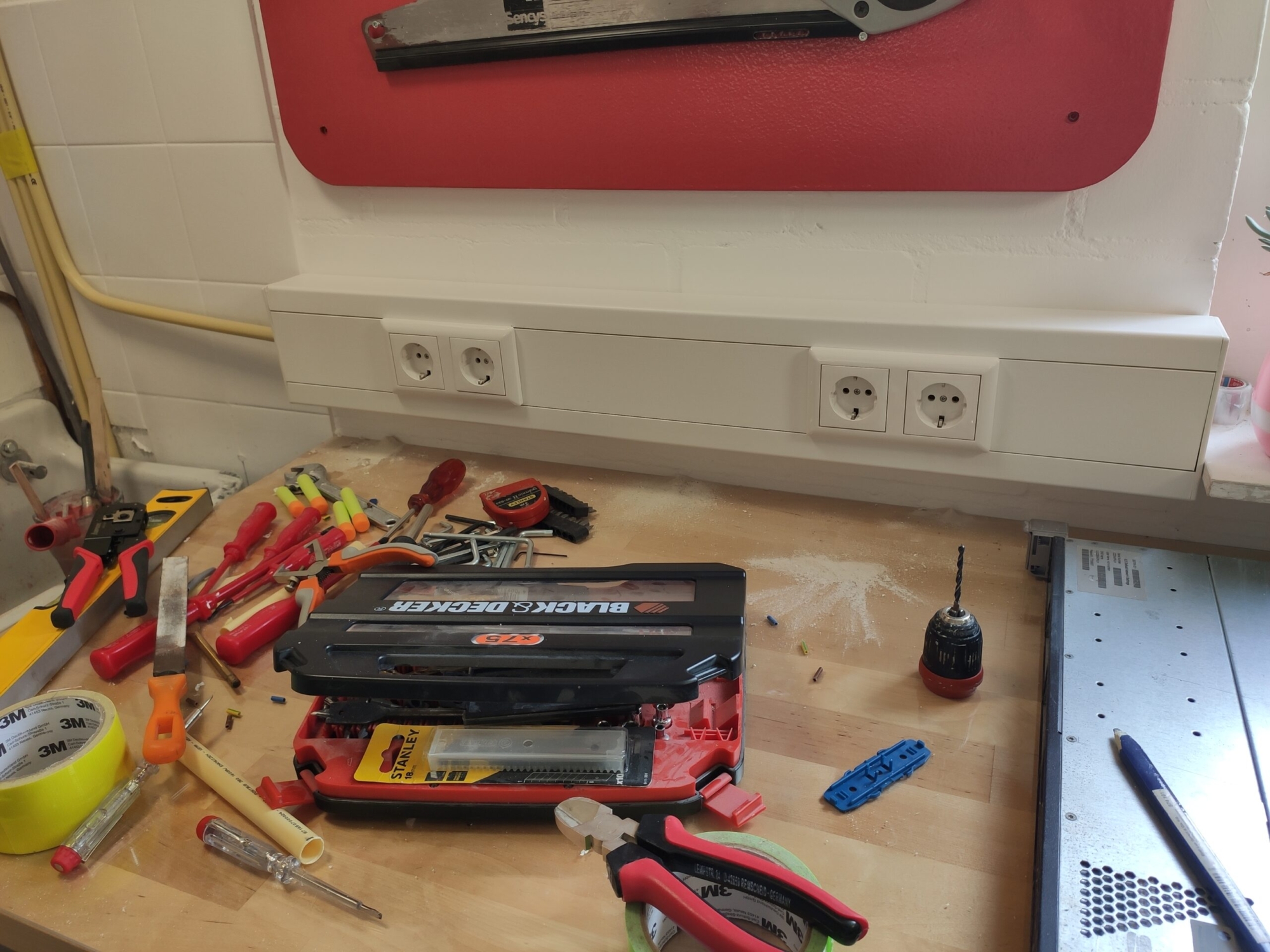

Finally, extra wall sockets and network connections have been installed in the workshop for all the power tools. The workshop has a total of 20 sockets and the office 10 sockets. Sufficient network connections are also provided to connect all computers, printers and other network equipment.

After months of hard work, the old garage has been converted into a real man cave. A luxurious office with kitchen unit and spacious desks, and a sleek workshop with space for both fine tinkering and coarser work. The end result speaks for itself.

Airco

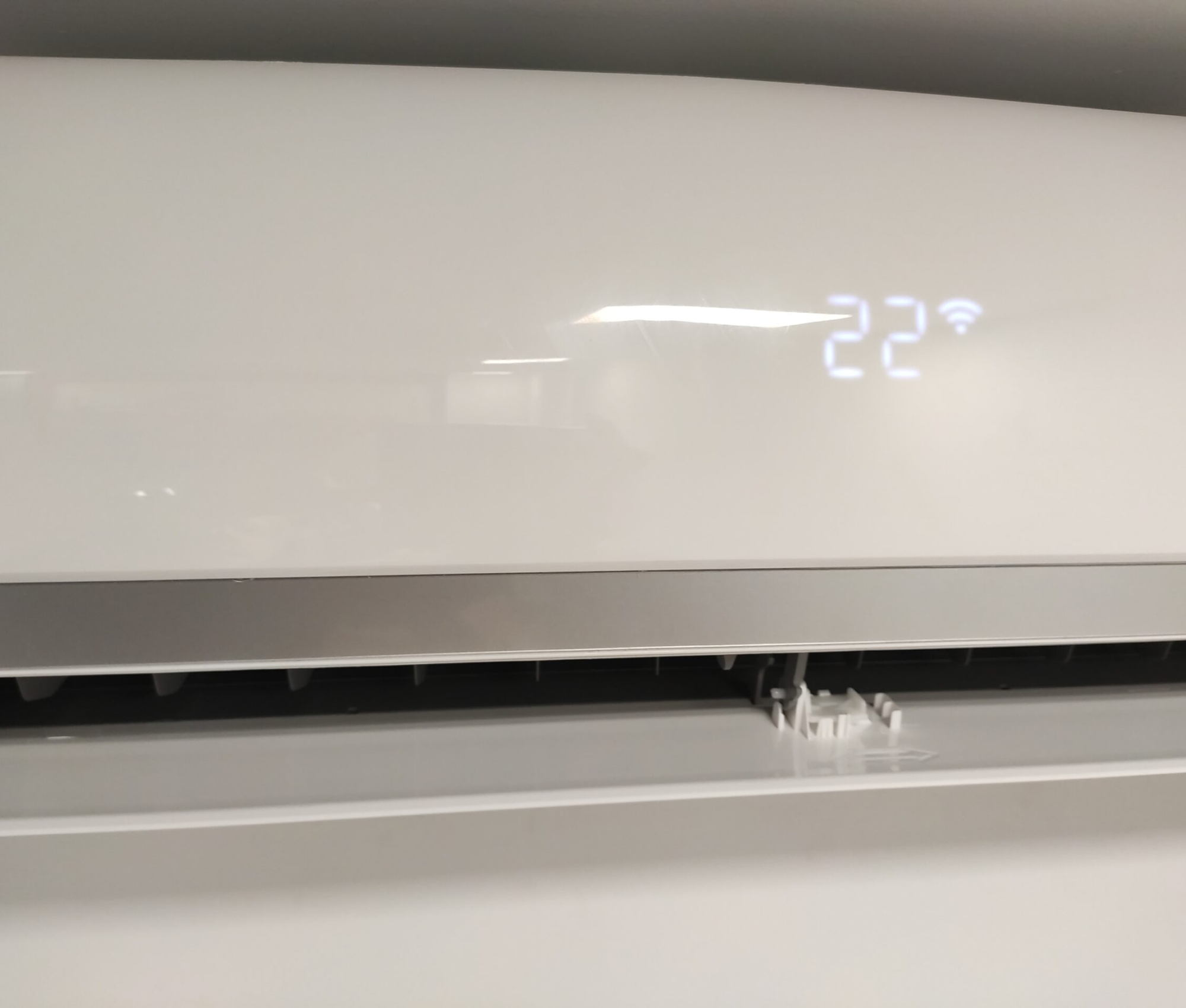

A disadvantage of the garage is that it has a flat bitumen roof. This means that the garage can get very hot in the summer, despite all the insulation. In order to be comfortable with it, Gijs decided to install an air conditioning. An additional advantage is that many air conditioners nowadays are also able to heat, and achieve a very high efficiency. By installing such an air conditioner, Gijs is also warm in the winter.

Air conditioners are a luxury product in the Netherlands, and therefore expensive. In southern Europe, however, every house has air conditioning, it is considered standard there and is therefore less pricey. This is why Gijs decided to import an air conditioner. As you might guess, the shipping costs of an air conditioner are on the high side. Gijs had to pay 200 euros for this because the air conditioning would be shipped per pallet. Because a maximum of four air conditioners fit on a pallet, Gijs decided to order four and thus split the shipping costs. He resells the other three air conditioners.

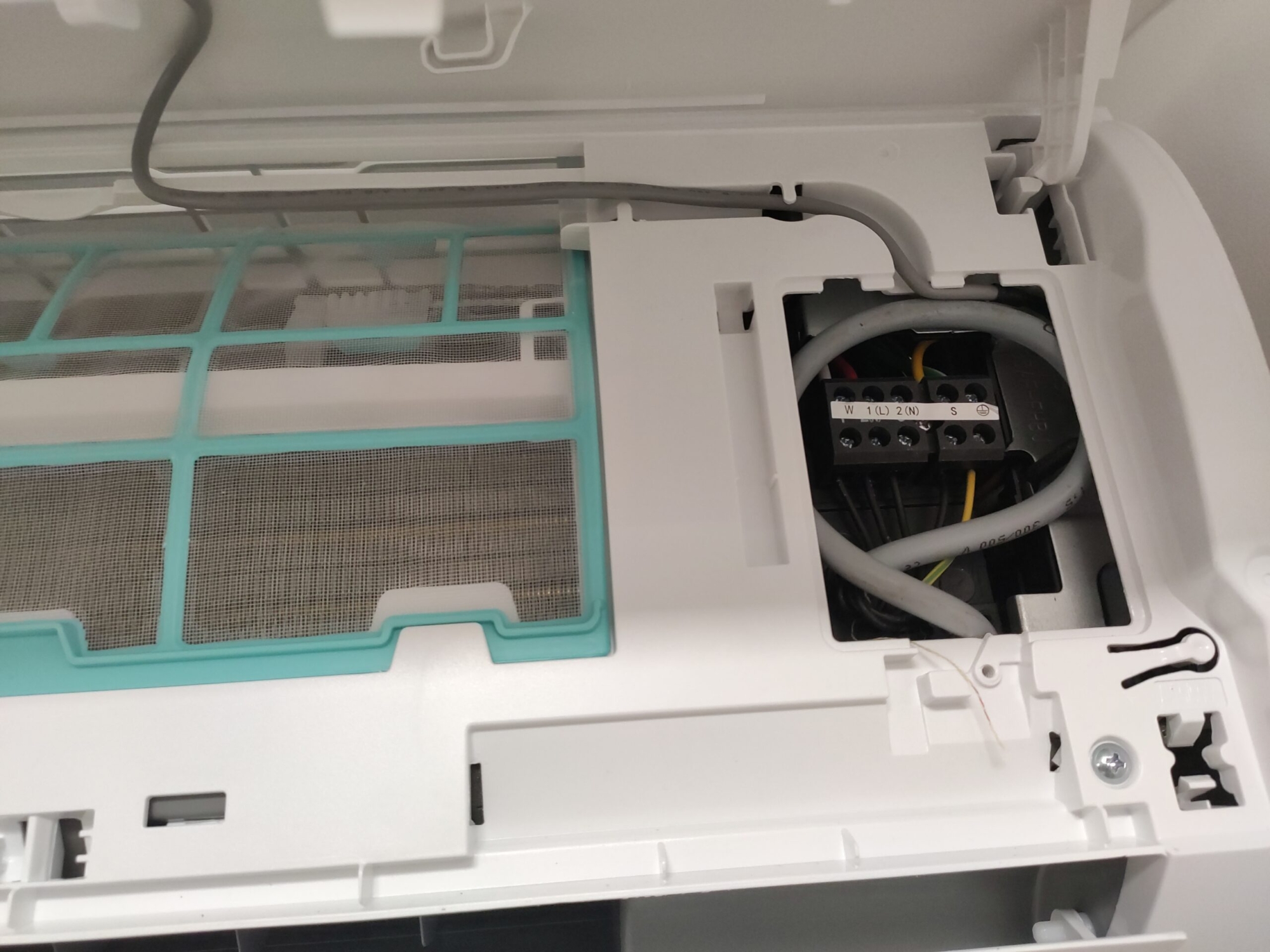

Installing an air conditioner is actually a breeze (pun intended). The indoor unit is mounted to the wall with a special mechanism. Three pipes and a cable come out of the indoor unit, Gijs routes them through a hole of about 6 centimeters behind the indoor unit in his wall. For this he uses a so-called dry drill.

Two of the pipes have to be connected to the outdoor unit of the air conditioner, through which the gas for transporting heat will flow. For most air conditioners, the outdoor unit is pre-filled for a certain pipe length, usually this is 5 meters. As long as the indoor and outdoor unit of the air conditioner remain within this distance from each other, there is no reason to add extra gas and the air conditioner can easily be installed without professional help.

The third pipe is for draining the condensation water in the indoor unit. When an air conditioner cools, condensation forms on the cooling fins. This flows into a receptacle and is transported out through this tube. Because this often happens passively (without a pump), it is important that this tube descends. Otherwise, the air conditioner’s indoor unit will fill up and start to leak, which is disastrous for a plaster wall.

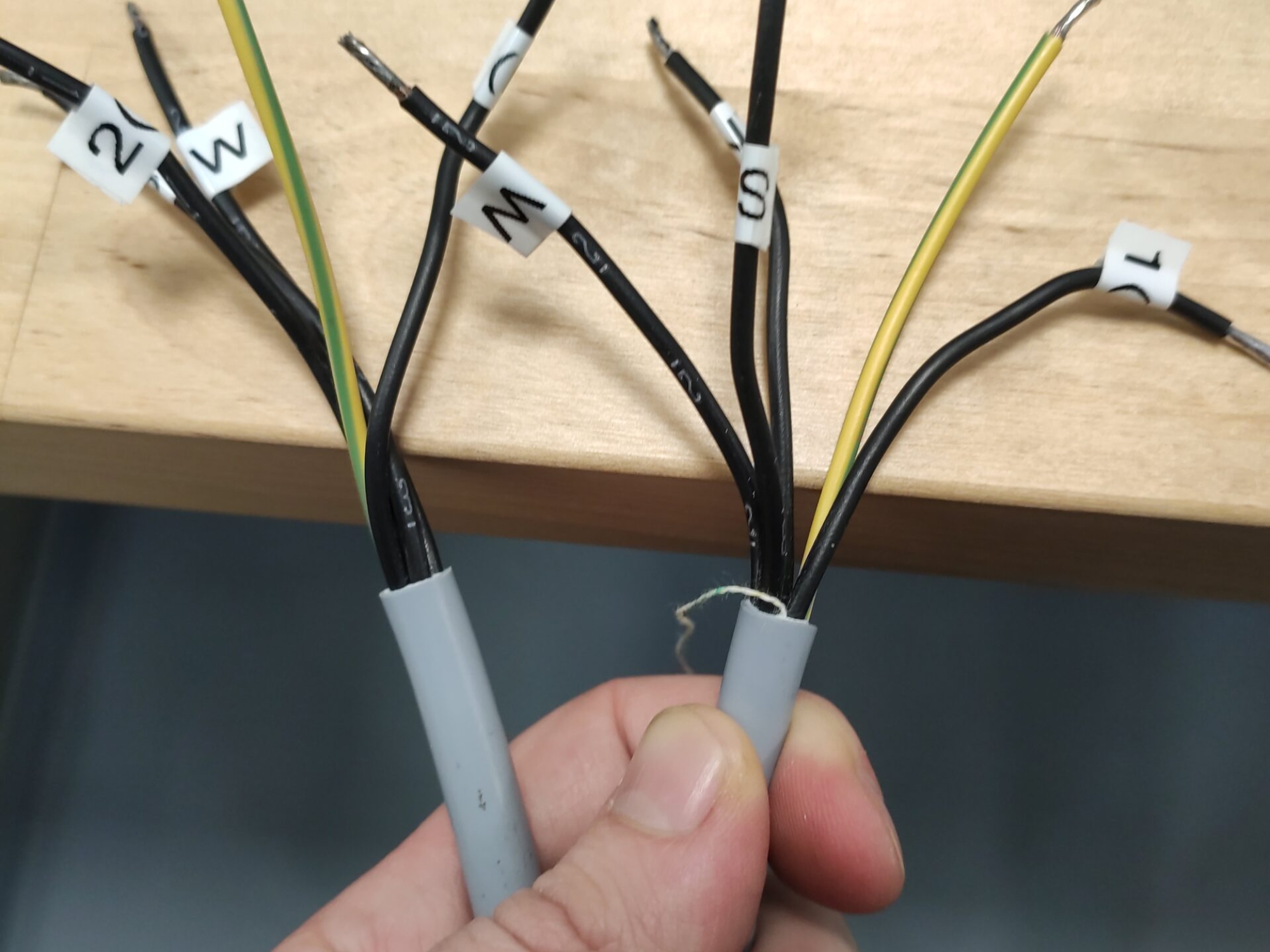

Finally, there is the cable to connect the indoor and outdoor unit. The indoor unit is powered by the outdoor unit and the two units must also communicate with each other. That is why there is a five-core cable to connect both units. For the sake of clarity, Gijs pre-labeled the cables.

Because the wall consists of 3 layers (outer wall, cavity wall and plaster wall), the various pipes and cables can get stuck in the spaces between the walls. Gijs tapes all the pipes together so that they can be fed through the hole as a whole. The hole is then filled with polyurethane foam to keep drafts and moisture out of the wall.

After the indoor unit has been installed, it is time to mount the outdoor unit. Because the roof of the garage is flat, Gijs decided to place the outdoor unit here with shock-absorbing legs. The legs, in combination with extra shock absorbers, must dampen the vibrations and thus the noise of the outdoor unit. These shock absorbers will also protect the bitumen roof against vibrations.

Unfortunately, Gijs ordered the wrong size mounting material, but after a slight modification the outdoor unit could be mounted on its feet and placed on the roof. Once on the roof, the pipes for the refrigerant gas can also be connected. It is important that these pipes do not leak, because the air conditioning will not work without refrigerant gas. Gijs tightens the pipes firmly and uses a special paste on the threads of the fittings to seal them airtight.

To minimize the air that can mix with the refrigerant gas and to check the system for leaks, Gijs uses a special vacuum pump and special barometer. Because this is very specific and expensive tool, Gijs decided to rent it. With the vacuum pump, Gijs can suck all the air out of the pipes and indoor unit before opening the taps on the outdoor unit. After fifteen minutes to 20 minutes, Gijs is pretty sure that the pump will not draw more air from the system, so he turns off the tap between the pump and the barometer and turns off the pump. This creates a closed system between the indoor and outdoor unit of the air conditioner. If after about fifteen minutes the pipes are still under vacuum, Gijs is pretty sure that the pipes have no leakage. Now Gijs can open the taps on the outdoor unit one by one to let the gas flow through the pipes. Only when both the taps are open Gijs disconnects the barometer. Because the pipes are under pressure, a very small amount of gas will escape, but no air will enter the system.

Because vacuuming and checking the system takes some time, Gijs has also connected the Electra of the air conditioning in the meantime. The five-core cable between the indoor and outdoor unit and the power supply to the outdoor unit. After everything is connected, it is time to test the air conditioning. Fortunately, everything seems to work in one go, so it is time to finish the pipes neatly. As extra protection against external influences, Gijs decided to wrap the pipes in an extra layer of insulating tape. He will also install a cable duct along the outer wall to hide the pipes from view. The end result is a neatly installed air conditioner to keep the office and workshop at a comfortable temperature all year round.

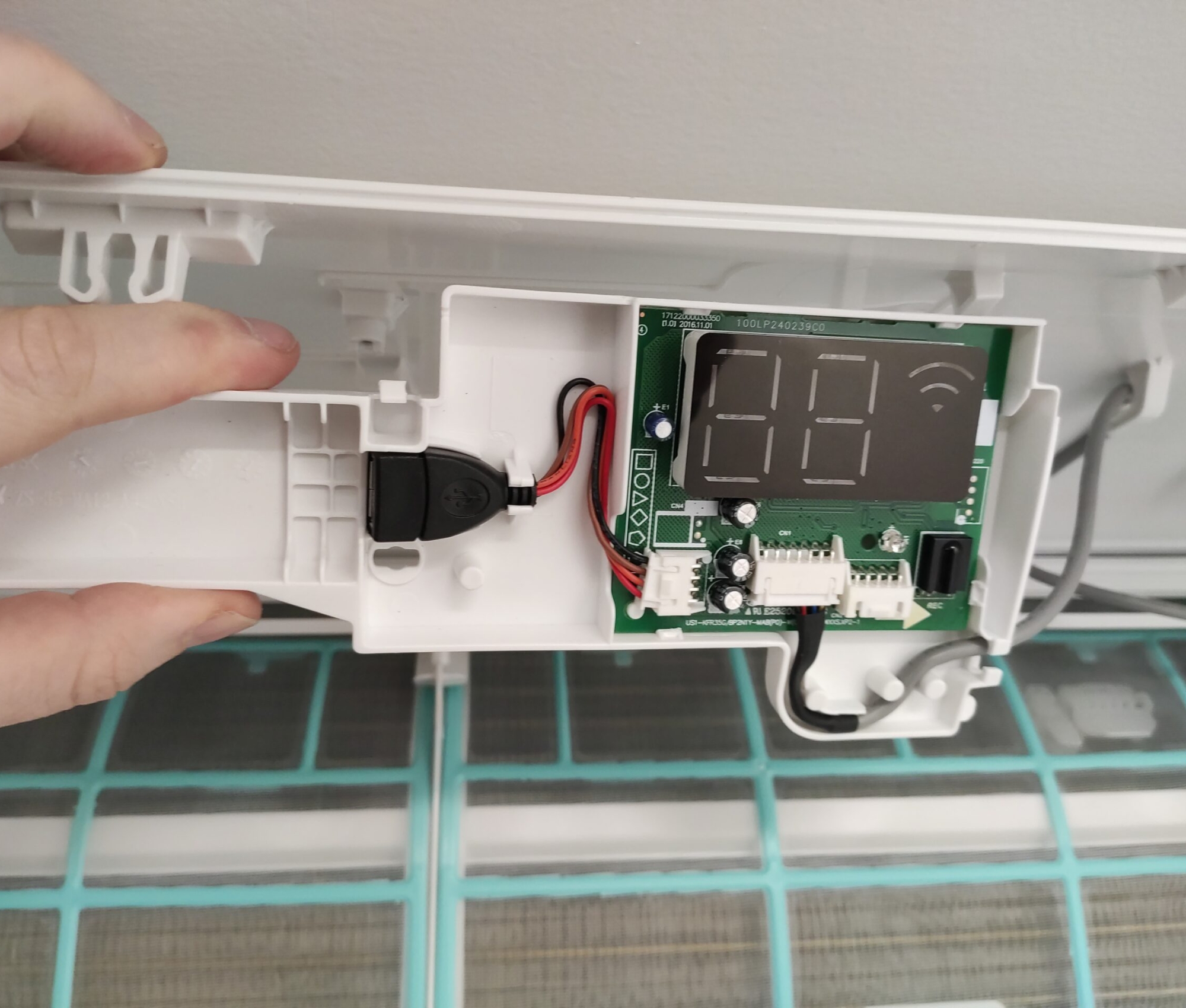

Because Gijs is a fan of smart gadgets, he is expanding his air conditioning with a WiFi module. A USB connection is hidden under the cover of the indoor unit. By connecting a special WiFi module to this, the air conditioning can be operated with an app via the internet. In addition to the standard app, the manufacturer also offers the option of operating the air conditioning with google home. In this way, Gijs can set the temperature of his office remotely, so that the office is already at the right temperature when Gijs enters. Also, with the help of google home, the temperature can be automatically adjusted when Gijs leaves his house. This makes it easy to save on energy.